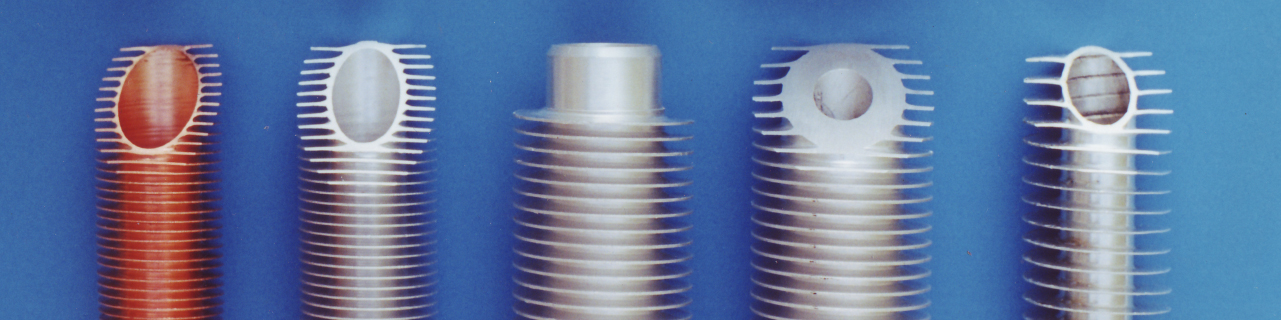

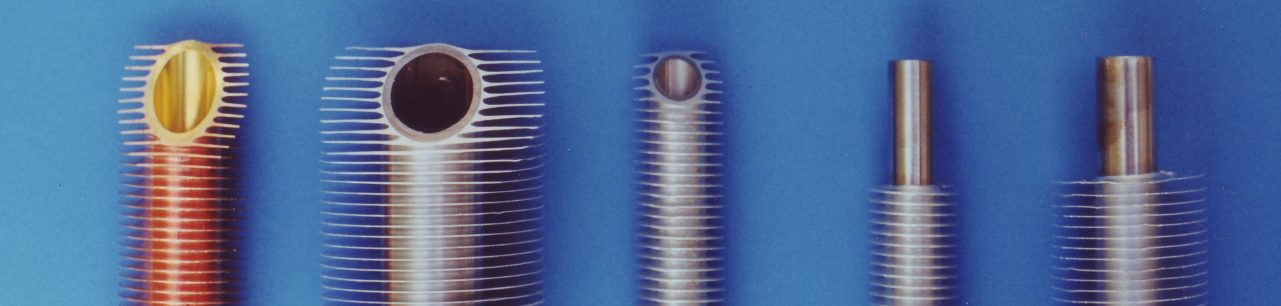

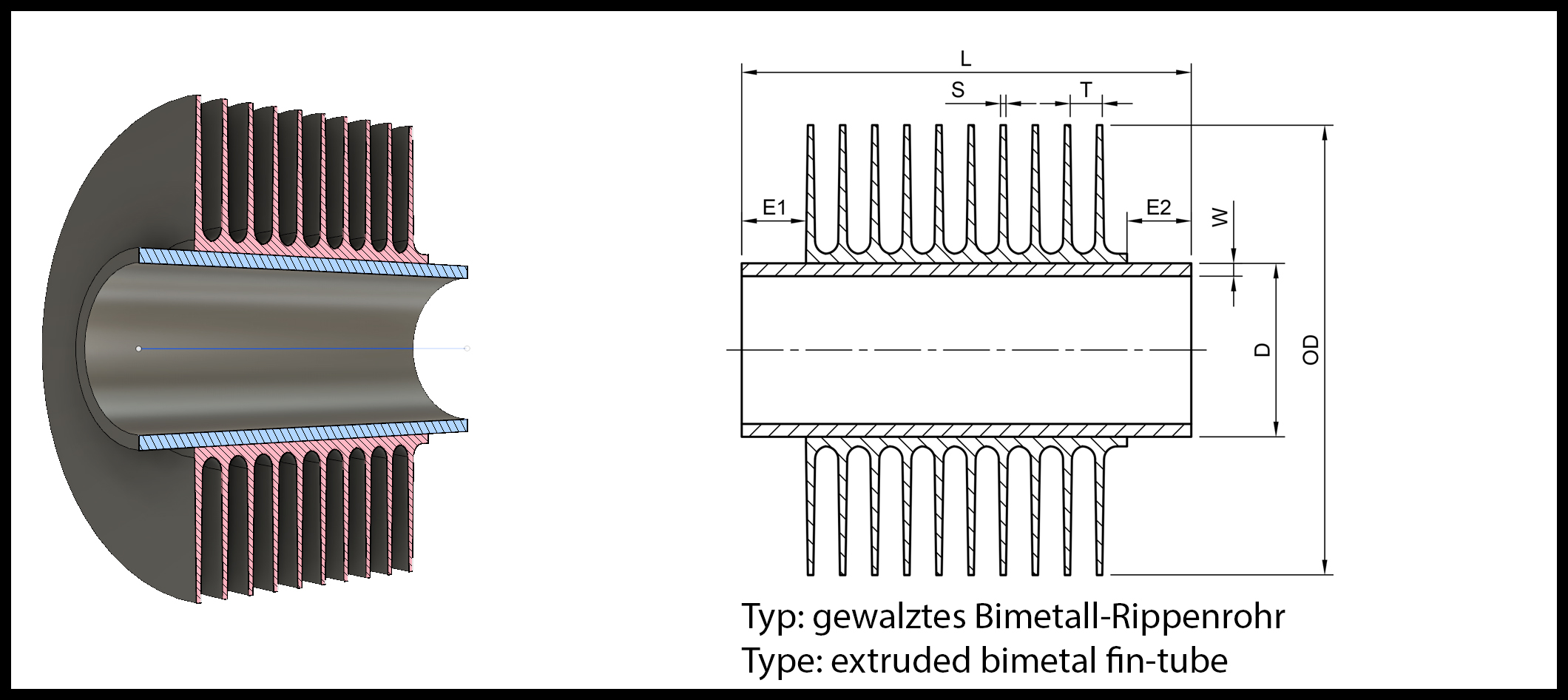

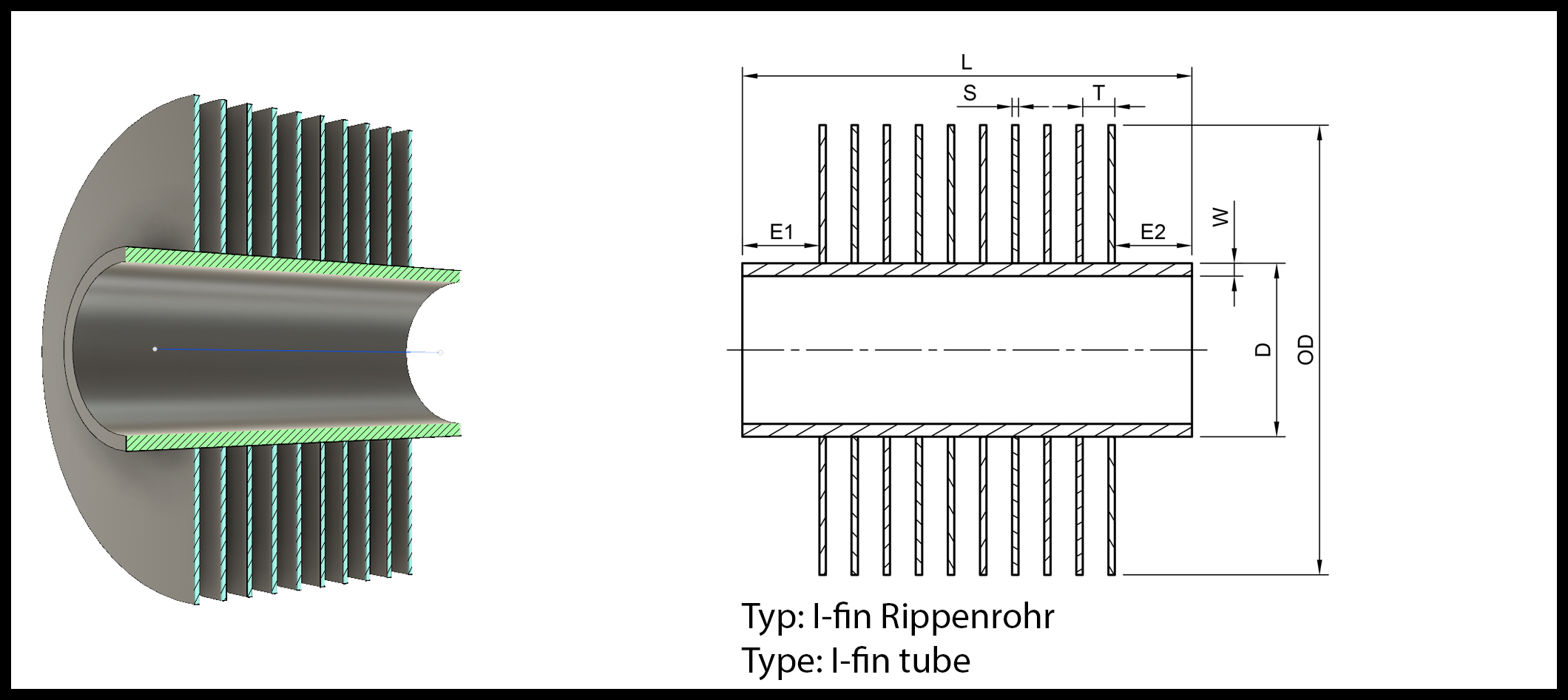

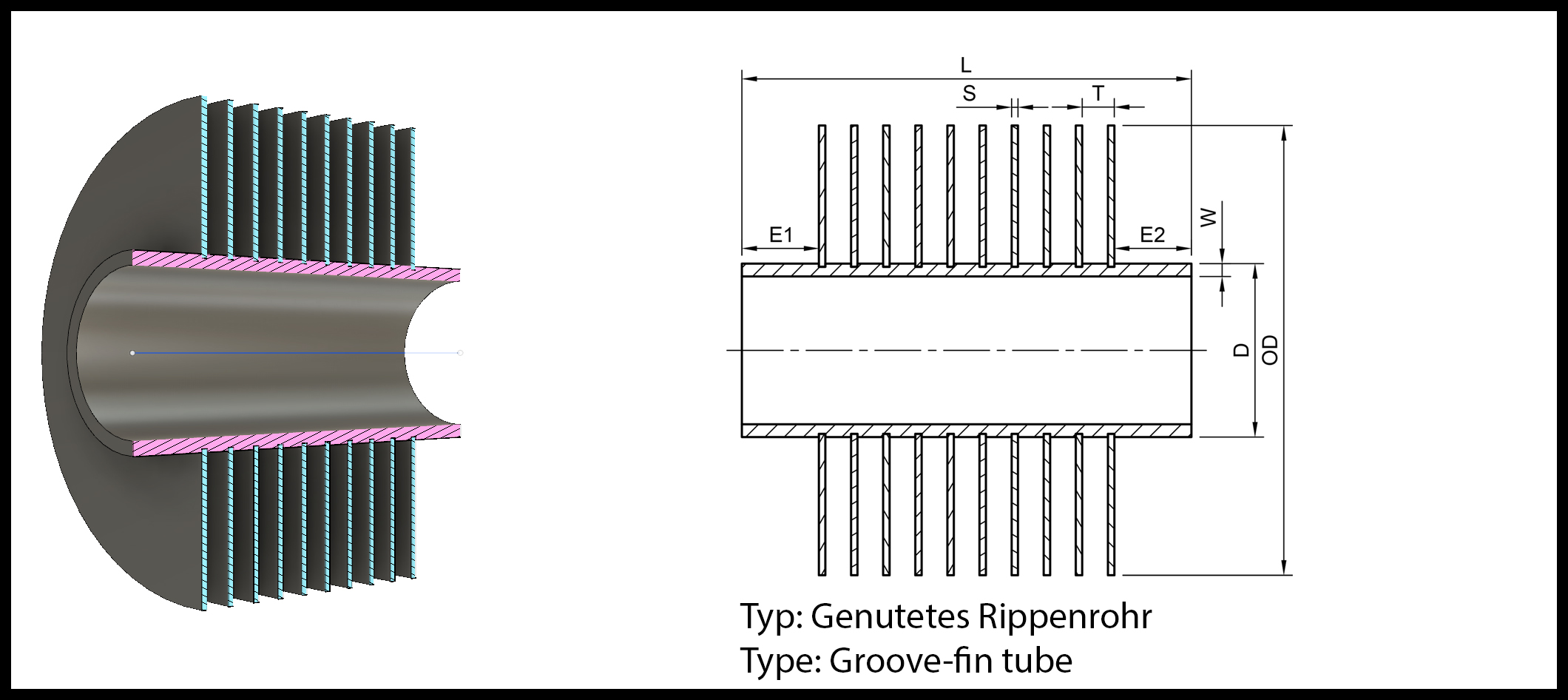

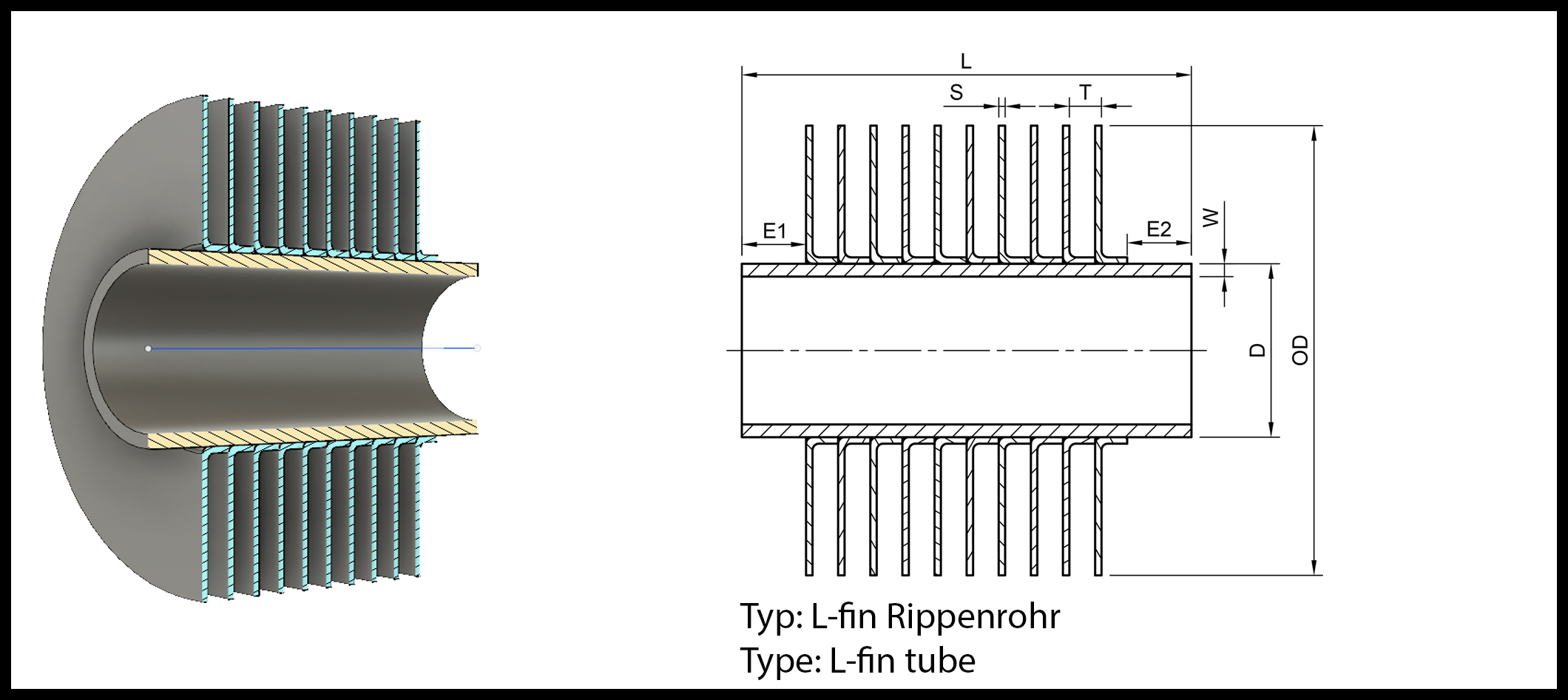

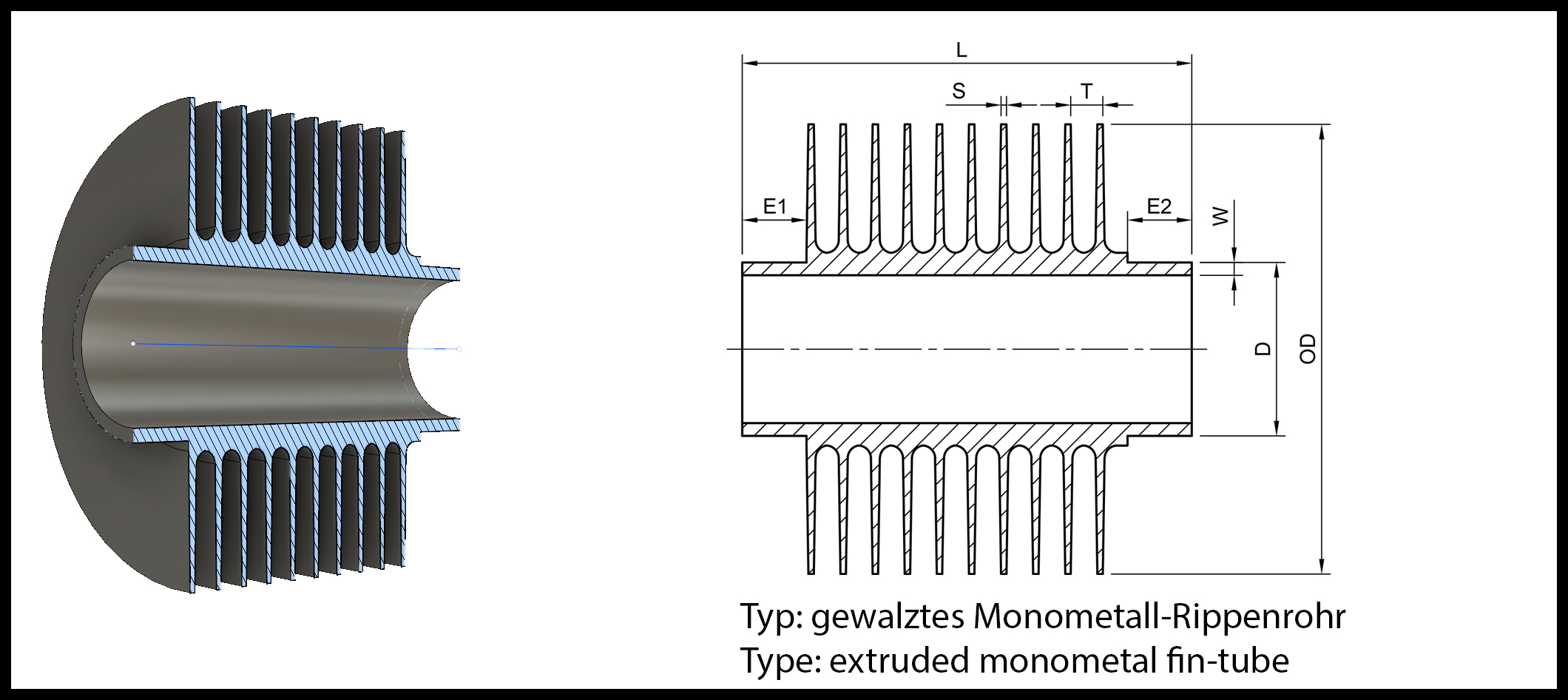

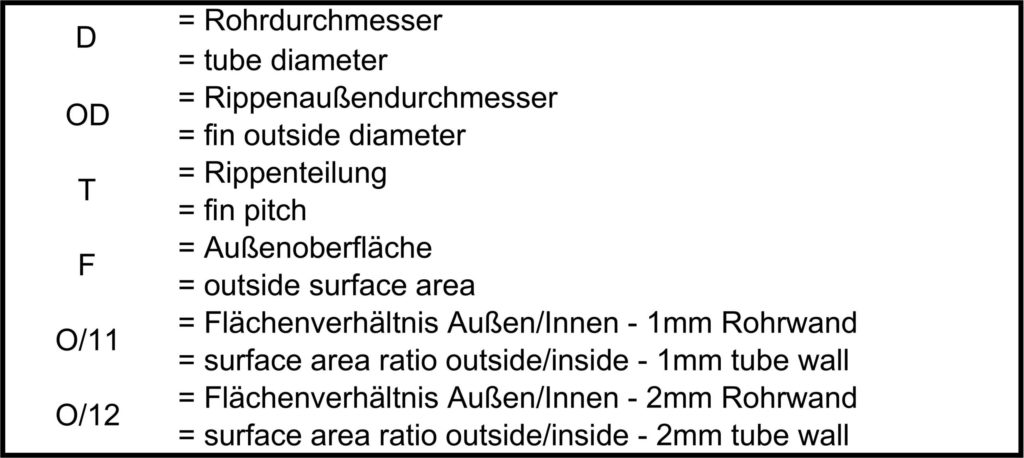

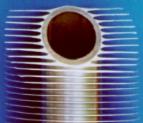

Finned tubes for the highest demands in durability and heat conduction. In a process similar to thread rolling. we roll and extrude a highly thermally conductive material such as aluminum or copper onto a core tube. An endlessly manufactured spiral finned tube is created. The fins are mechanically very resilient (roll hardening) and sit extremely firmly on the core tube. The fin material is covering the surface of the finned tube only and therefore there is no risk of electrostatic cottosion. The profile of the fins are shaped so that optimal heat transfer and lowest possible flow resistance is guaranteed. Extruded finned tubes are produced in bi-metal (with inner tube) and mono-metal (without inner tube) design.

Extruded finned tubes are used for:

- Gas cooler

- Gas heater

- Process cooler

- Air coolers, cooling towers

- Condenser

- Drying kilns

We manufacture:

Standard dimensions

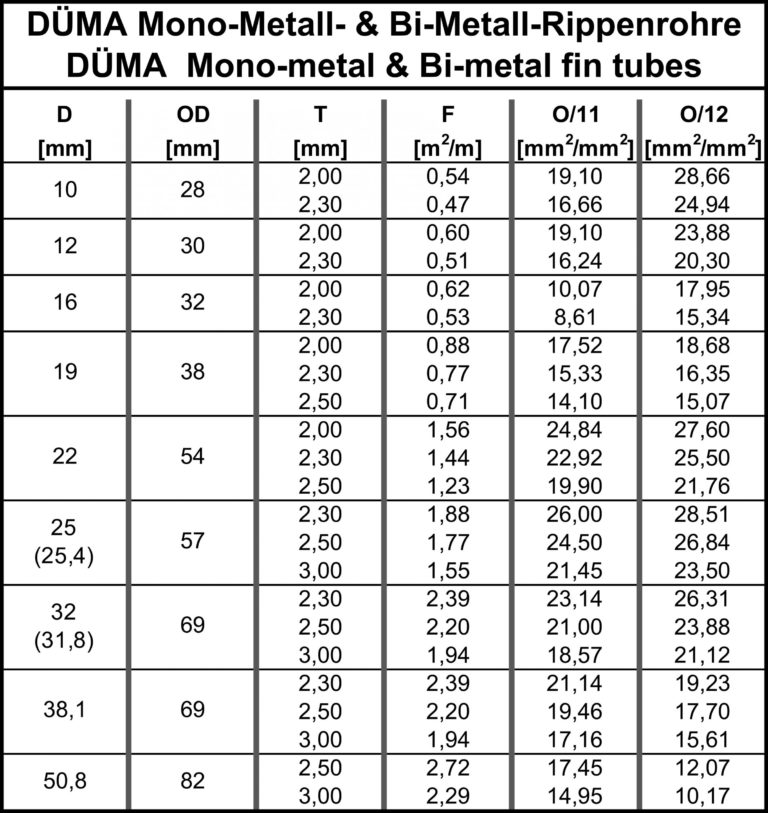

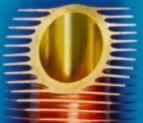

Here is the overview of our standard dimensions for our various fin types. Other dimensions on request.

Mono-metal fin tubes & Bi-metal fin tubes

max. fin height 18mm, max. diameter of tube: 51mm

Other dimensions on request

Please send us quantity and dimensions of the finned tubes in your inquiry. We deliver the finned tubes in the requested length. Ends without finns will be produced on demand. Send us an email for your inquiry.

Aluminum Fin

Inner tube: any material

Aluminum

Rippen

mittlerer Höhe

Aluminum

Copper

Rippen: Kupfer

Innenrohr: Messing

Aluminum

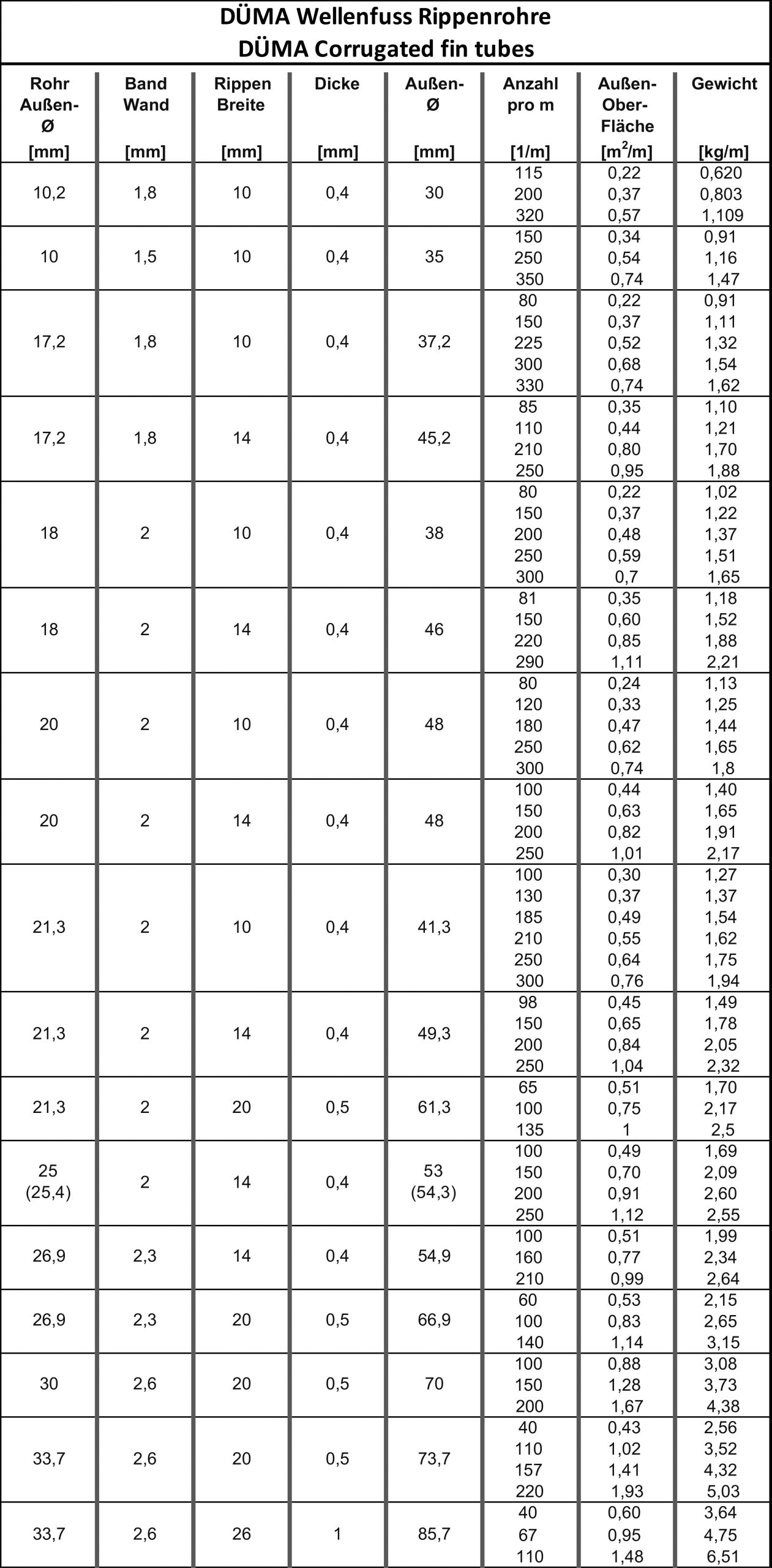

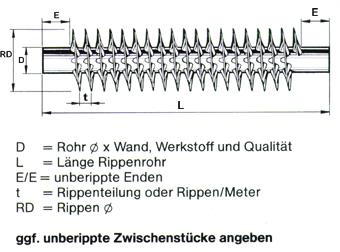

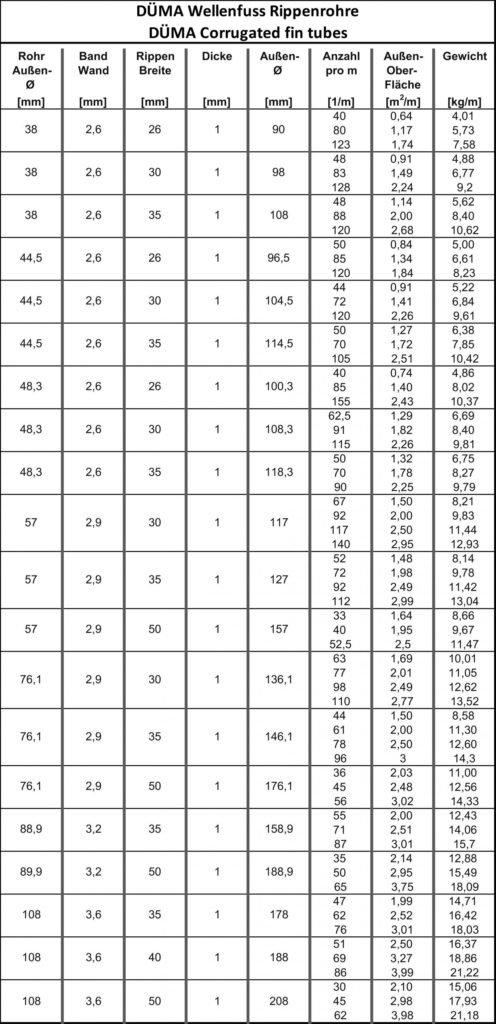

Corrugated fin tubes

Corrugated fin tubes are made of steel - black, galvanized, powder steem coated or in stainless steel.